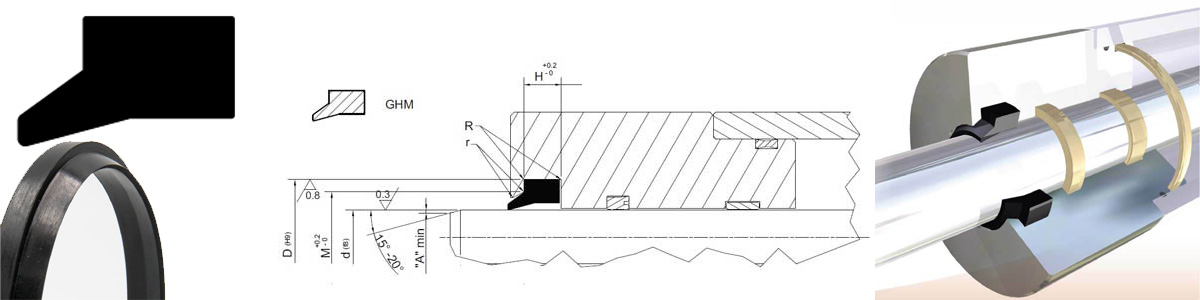

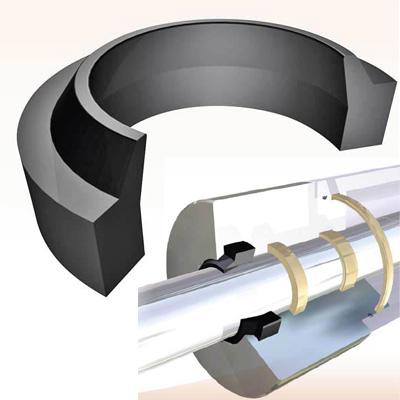

| Ghm: single effect closed slot mounting |

| Material |

Speed ​​m/s |

Temperature °C |

Pressure Mpa |

| Nbr |

0.8 |

-30 +110 |

0 |

| Nbr/brit |

0.8 |

-50 +100 |

0 |

| Viton |

0.8 |

-20 +200 |

0 |

| Epdm |

0.8 |

-40 +160 |

0 |

| |

The GHM type scrapers , made of NBR rubber material , represent an essential component for the protection of the various parts in hydraulic and pneumatic equipment. The main task is to prevent the infiltration of dust, mud or any other body foreign to the fluid into the cylinders which, in addition to compromising the functioning of the seals, would damage the surface of the cylinders and rods due to their abrasive action. This type of scrapers is particularly suitable for equipment located in humid and dusty environments. Due to their particular profile they are easy to assemble thanks also to the simple machining of the seat. In the presence of particularly harsh conditions and/or high temperatures, they can be produced in alternative materials, for example in FKM.

GENERAL CHARACTERISTICS

Easy assembly

High abrasion resistance

High resistance to extrusion

Low deformation value

APPLICATIONS

-Construction machines

-Forklifts

-Injection molding machines

-Agricultural machinery

-Lifters

-Standard cylinders

Ghm are interchangeable with: WRM - A - P6 - A5 - NBR - 33 - A40 - AE40 - MWM - G6 - PWM - WM - MKW - WS-10 - FPWM