- Home

-

- Product

-

- Back-Up Rings

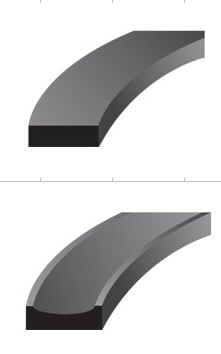

Back-Up Rings

Description

Back-up washers or Anti-extrusion rings are designed to protect o’rings and help prevent extrusion in high pressure applications by closing the clearance gap. Double acting applications (using bi-directional pressure) require the use of two back-up rings, one on either side of the o’ring.

In single acting applications (single sided pressure) where only one back-up ring is required, the back-up is located on the low pressure side of the o’ring; although it is often recommended that two back-ups be used in single acting applications to mitigate the possibility of installing the back-up on the wrong side of the o’ring.

Seal Solutions Australia stock a wide range of back-up rings to suit imperial and metric sized o’rings. Compounds available: 90 Duro nitrile, 90 Duro Viton, Teflon and polyurethane.

| Title | Material | Temp | Pressure | Speed | Prod No |

|---|---|---|---|---|---|

| Back-up Rings PTFE (Teflon) | PTFE / Polymyte | -100° - +500° F | _ | _ | BUWM/PTFE |

| Title | Material | Temp | Pressure | Speed | Prod No |

|---|---|---|---|---|---|

| Back-up Rings - NBR/Polyurethane | NBR & Polyurethane | -40° - +200° F | _ | _ | BUWM/ U/N |

-

Excavator

Excavator -

Backhoe-Loader

Backhoe-Loader -

Loader

Loader -

Dozzer

Dozzer -

Bull Dozzer

Bull Dozzer -

Crane

Crane -

Forklift

Forklift